Noxmat offers a full range of high-efficiency heating solutions designed for industrial furnaces. From high-velocity gas burners to smart recuperative systems, our technologies help U.S. manufacturers lower natural gas costs, reduce NOX emissions, and meet evolving environmental standards — all with the support of our U.S.-based team in Michigan.

Ideal for non-ferrous metallurgy applications, the Wiedemann burner combines compact design with consistent thermal output. Engineered for easy integration into retrofit projects or new systems where space is limited.

Etamat is Noxmat’s most advanced burner system, featuring integrated steel or metal-foam recuperators. It delivers up to 90% combustion efficiency with very low NOX levels - ideal for demanding U.S. industrial operations.

Noxmat’s RHGB recuperative burners use integrated heat exchangers to recover exhaust heat, preheat combustion air, and significantly lower gas consumption. Available in output ranges up to 250 kW and operating temperatures to 1150 °C.

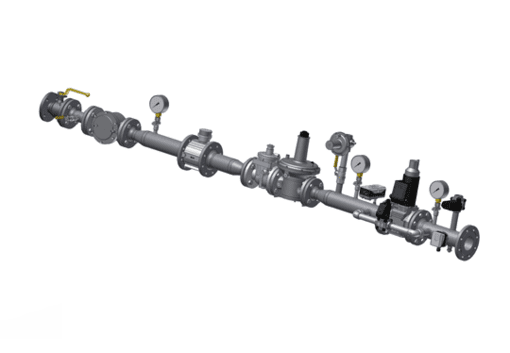

Noxmat supplies custom pre-assembled gas trains for safe and code-compliant burner operation. Configurations are designed to meet NFPA/UL requirements and are tailored to each combustion system.

Noxmat’s high-velocity burners provide fast heat-up times and excellent flame control — ideal for continuous or batch furnace lines requiring stable, high-energy combustion.

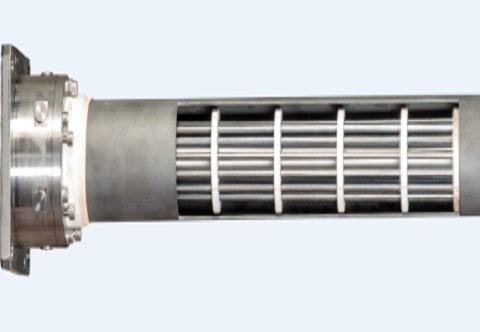

For gas-restricted environments or precision applications, Noxmat supplies electric heating elements tailored for industrial furnaces and radiant tubes.

Whether you're operating a forging line, heat treat furnace, or continuous kiln, Noxmat delivers heating systems designed to meet the highest industrial standards. Our products are in use across the United States in: