The high efficient NOXMAT recuperator burner ETAMAT sets new standards in energy savings with a combustion efficiency of up to 90%. Available in a power range from 15 to 35 kW, burners of this series achieve the highest possible heat recovery thanks to a special recuperator.

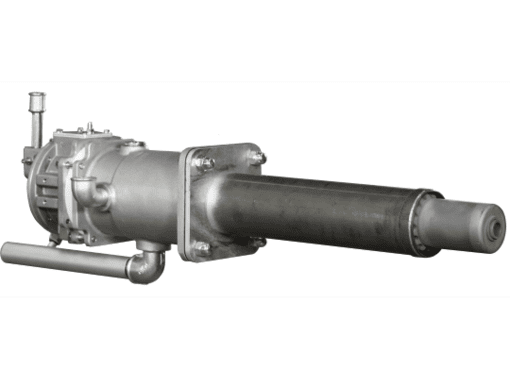

The NOXMAT retrofit recuperator burner REMAT is characterized by its easy installation in existing systems, but also by higher energy efficiency, significantly reduced wear and less expensive maintenance.

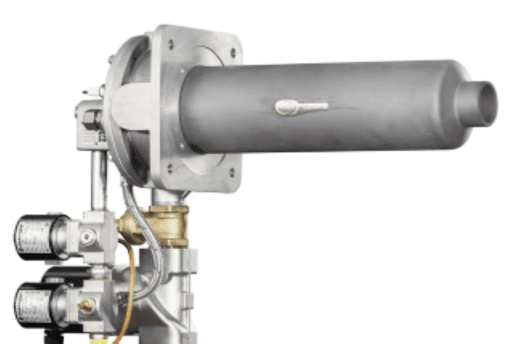

The NOXMAT cold air burners of the HGBE series are available in a power range from 9 to 160 kW. They are suitable for cold and preheated air operation (up to 400 ° C air preheating). The large flame pulse, which is immediately present when the burner is started, improves the temperature uniformity in the thermoprocessing system..

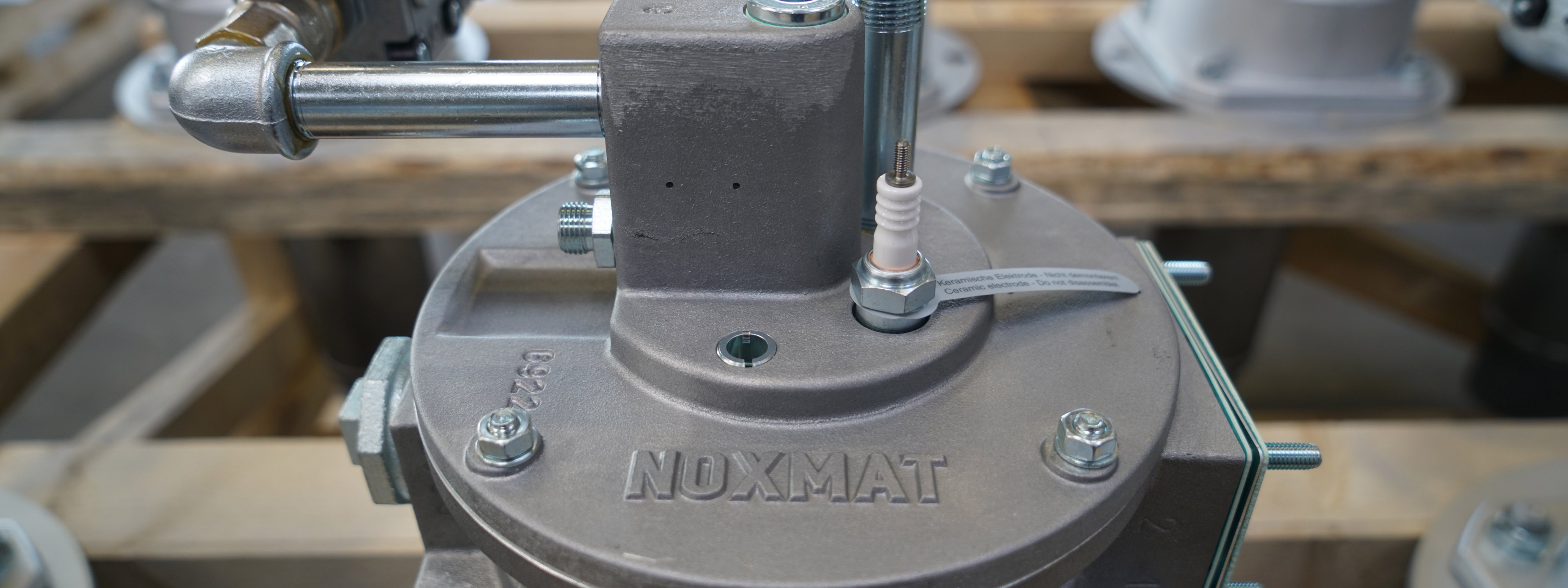

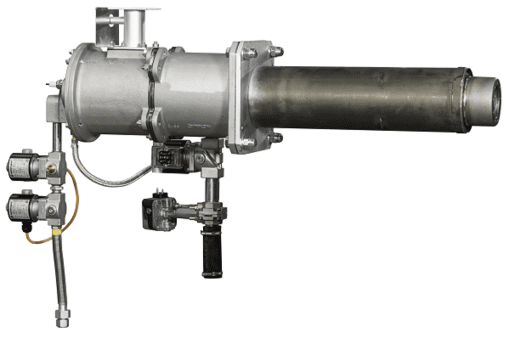

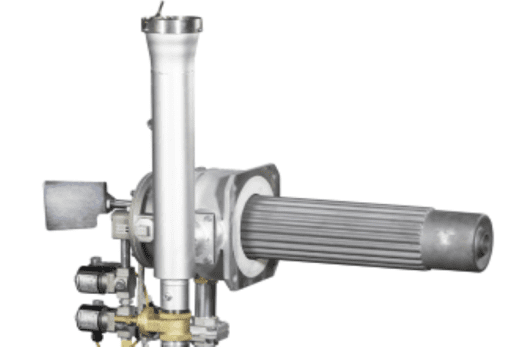

The classic NOXMAT recuperator burners (RHGB) improve energy efficiency through the internal preheating of the combustion air. They are suitable for the direct and indirect heating of industrial furnaces up to an application temperature of 1150 ° C and are available in a wide range of outputs from 7 to 250 kW.

The ceramic NOXMAT recuperative burners of the K-RHGB series improve energy efficiency through the internal preheating of the combustion air. They are suitable for the direct and indirect heating of industrial furnaces up to a maximum application temperature of 1300 ° C and are available in a wide range of outputs from 9 to 250 kW.

The single-stage recuperator burners (K-RHGBE) are an inexpensive alternative to the classic recuperator burner. Suitable for direct and indirect heating of industrial furnaces up to an application temperature of 1,300 ° C and available in a wide range of outputs from 9 to 100 kW.

NOXMAT continues the products of the burner manufacturer Wiedemann. These are tubular recuperative burners for non-ferrous metallurgy, cold air burners and flat flame burners.